Manufacturing

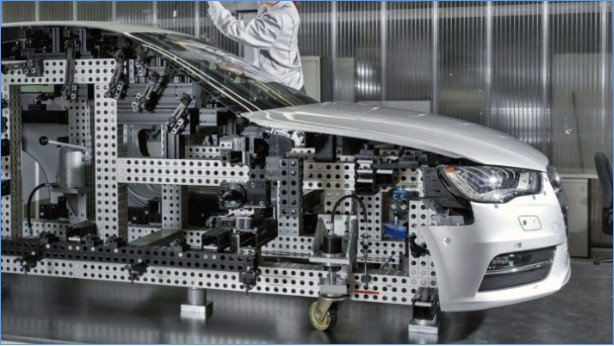

Design, Manufacture and Installation of Jigs

Assembly Jigs are necessary for the assembly of automobile. It is a tool used to grip the automotive part to connect various parts together to assemble a vehicle. Assembly Jigs are a made-to-order product for specific line of production or model of vehicle.

AAPICO provides a full service for design, manufacture, and installation of jigs, from concept to commissioning, including design, simulation, welding, ergonomics and time studies, and manufacture of tooling.

Prior to delivery, a team of engineers conducts assembly trials and validation measurement at our inhouse try-out facility. The Company also provides on-site support at the customers’ assembly locations. The installation and the commissioning team has supported customer launches globally in China, India, South America, Southeast Asia, and other countries.

We are able to provide solutions for complex & diverse volume scenarios.

Our flexible assembly designs minimise floor space requirements whilst increasing the ability to build different models in common cells.

Built Bodyshop Assembly Jigs for a single model, for up to 5 different countries almost simultaneously.

Designed, built and installed an automated assembly facility for 420,000 pick-up truck chassis frames per year.

AAPICO is one of the first Thai companies that is able to provide customers with the “full turnkey body shop” solutions. The company is one of best makers for low-volume, manually operated body assembly jigs. As the market for low-volume jigs in Thailand is small, the company has focused to market its products overseas and invest more in research and innovation to enhance its products and expand services to serve customers’ requirement.